Suit/Armor Thermal Management

- High-Performance electroformed heat pipe

- High-Performance electroformed microchannel heat exchanger

- Comparing heat sink designs and products on the market

- High Strength Metal

- Research Proposal

- Current research examples

High-Performance electroformed heat pipe

Heat pipe wick

Voids between high thermal conductivity diamond particles form enhanced heat pipe wick and channels.

|

|

Examination of particle uniformity

|

|

High-Performance electroformed microchannel heat exchanger

- Cooling capacity: Demonstrated > 5000 W/cm2.

- Stress-free direct contact with die.

- Made of stacked electroformed layers with high thermal capacity microchannels.

- Microchannels have laminar flow, with the enhanced heat transfer coefficient inversely proportional to the width of the channel (heat transfer coefficient increases, as width decreases).

Diamond heat exchanger design

Thermally conductive diamond particles to connect two conducting surfaces together.

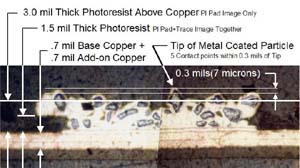

Particle Interconnect via

Connecting two conducting surfaces together.

| Particle closeup | Connector closeup |

|

|

Comparing heat sink designs

Comparing heat sink designs and products on the market

High Strength Metal

SEM, FIB, AFM pictures of metal

Research Proposal

- PI Tek proposes to develop a personnel thermal management suit/armor system allowing wider operating temperature range than current protective clothing; thus improving individual combat effectiveness.

- PI Tek proposed suit/armor will integrate water storage better than current add-on "CamelBack".

- PI Tek proposed thermal suit/armor system would require only addition of gloves and facemask to complete highest level MOP.

2-Phase Research Proposal

- Research and study innovative suit/armor configurations for MOP protection using a 2-Phase Research Proposal Model.

- Phase 1 - Correlate theoretical data to actual data using instrumented samples of MOP.

- Phase 2 - Fabricate & test suit/armor incorporating optimized configurations from Phase 1.

Phase 1 Study

- Create CAD model of potential suit/armor compositions to optimize thermal cooling capability.

- Fabricate chest size sample of optimized candidates.

- Perform thermal stress testing of instrumented samples to confirm model accuracy.

- Correlate theoretical data to actual data for model correction.

- Report theoretical data vs. actual data results.

Phase 2 Study

- Create CAD model of potential suit/armor compositions to optimize thermal cooling capability.

- Fabricate upper body size sample of optimized candidates.

- Perform prolonged wearability thermal stress testing of instrumented samples to confirm model accuracy.

- Correlate theoretical data to actual data for model correction.

- Report theoretical data vs. actual data results.

Customer Provided

- Provide 2 MOP suits (both will be returned at conclusion of testing. Required for baseline modeling to judge performance increase.)

- Provide 2 "CamelBack" water storage systems currently in use.

- Ergonomic body model and dimensions.

Current research examples

Advanced Lightweight Microclimate Cooling System (ALMCS)Technical Support Working Group, Body Armor Cooling System...

The ALMCS is an electrically driven vapor cycle cooler that circulates a chilled fluid through a heat transfer garment, lined with a network of tubing. Metabolic heat from the wearer is transferred to the fluid, which is pumped to the ALMCS where the heat is rejected. The coolant fluid is re-chilled and re-circulated back to the heat transfer garment. The ALMCS operates on two BA-5590 lithium sulfur dioxide (LiSO2) batteries, although a third battery may be added for enhanced performance.

...