Automotive Spot Weld

Evaluated with Delco and General Motors.

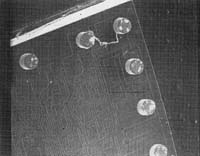

Particle Interconnect - Hughes Aircraft 1988 - 1989

50,000 die joint production test venture.

Before burned-in:

- No bump deformation.

- Die Sn/Pb 3/97, socket Au 100, load 1 gm/mil2 pad to socket. Burned-in 125 ° C for 168 hours. Particles milled into gold ceramic ink and fired onto ceramic substrate. (Depression in center of bump is aluminum die pad covered by protective passivation layer.)

|

|

| 50x bumped chip before pressing against PI gold thick film. | 500x bump before contacting PI. |

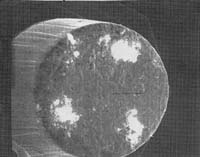

After burned-in:

- No bump deformation.

- PI/gold bonded to tin/lead bump and was ripped off substrate. Resulting in using nickel as higher strength Particle Interconnect bond layer in future test socket/temporary contact usages and other metal combinations in permanent usages.

|

|

| 50x bumped chip after pressing against PI gold thick film metal matrix with 1 gm/mil2 load. | 500x bump after contacting PI, metal matrix is on bump. |

Another tab frame cold welded to metal substrate

Aluminum to Aluminum, 300x magnification. Prior to pull test.

|

|

| Tab position two. | Tab position three. |

After pull test.

|

|

|

| 60x magnification. | The particles in nickel matrix plated onto the copper tab frame separated at the tab frame plating boundary (300x magnification). | Glass pulled out of microscope slide (300x magnification). |

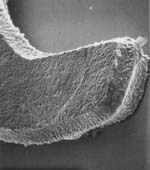

Aluminum coated drill bit with 10 micron diameter diamonds probing mirror smoothed aluminum

(a) 2000x magnification, 60 degree angle.

First sign of cold diffusion weld, showing the site where aluminum coating is peeled off.

(b) 2000x magnification, 60 degree angle.

First evidence of cold diffusion weld. Aluminum coating on diamond drill bit is peeled off and left on mirror smooth aluminum as result of welding.

|

|

| a | b |