RF ID Tags

Current industrial design includes fuse on silicon chip. PITek.US design does not require fuse to be separately defined on silicon. Therefore, no silicon onto substrate assembly is required.

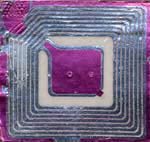

Typical RF ID tag.

Typical RF ID tag.

RFID Market

5-Cent Tag Unlikely in 4 Years

...

ARC found that in 2003, the average unit price of tag was 91 cents for a passive HF tag and 57 cents for a passive UHF tag. The firm expects that by 2008, the unit price will drop to an average of 16 cents for passive UHF tags, which vary by form factor, and to nearly 30 cents each for passive HF tags, although some tag manufacturers with high-volume contracts may be able to offer passive UHF tags for as low as 5 cents each. The tag manufacturing process will be a major factor affecting costs, according to Chantal Polsonetti, V.P. of manufacturing advisory services at ARC and author of the report, who says that "antenna attachment or tag assembly, not IC production, will be a primary supply-side inhibitor to increased volume and in turn lower cost tags."

...

One industry sector that Polsonetti says is not as sensitive to tag price is the pharmaceutical market, especially given that the U.S, Food and Drug Administration has recommended the use of RFID technology to create a "pedigree" - a secure record documenting that the drug was manufactured and distributed under safe and secure conditions (see FDA Endorses RFID Technology.

"The market potential here is huge, with over 12 billion units as candidates for tagging in the United States alone," writes Ponsonetti, who notes that because pharmaceutical drugs have a higher retail prices and higher margins relative to low-priced CPG products, they can accommodate RFID tags that cost more.

...

"Hands-free operations through use of fixed readers and other RFID infrastructure that are part of the factory or distribution center infrastructure will eliminate the incremental labor and material-handling costs associated with current slap-and-ship techniques," says Polsonetti. "The reduced need for manual handling associated with this approach has been attributed to anywhere from a 5 to 35 percent reduction in labor costs for a given distribution center. The promise of greater accuracy of shipments, plus reductions in the accompanied returns and processing, can also be beneficial."

...

RFID Applications

Safety, security, tracking, asset management.

Auburn University Detection and Food Safety Center Overview

...

With a cost of five to 10 cents, stamp-sized sensor tags (STags) can be placed on appropriate fresh-food products. With a target sensitivity of tens of cells, the sensors would transmit a host of information by non-line-of-sight radio frequency. For consumer safety, these sensors would measure temperature, bacteria count, and other chemical and environmental changes. For the food industry, these sensors would provide the same information, in addition to traceability features such as origin, date and time of processing, shipment information and a range of other "programmable" features. Our RFID STags would be found molded into the sides of plastic bottles, attached to the inside cap of glass bottles, molded into Styrofoam meat-trays and attached to plastic wraps.

...

...

At the Innovation Center installation, prepackaged meat items, each bearing a smart label, can be presented to the RFID reader in the kiosk. The kiosk's screen can then display a detailed account of that item's history in the supply chain, such as the animal's date of birth and the farm where it was raised, as well as perhaps the kinds of food it was fed, the date and place of its slaughter, and the name of the wholesale butcher. According to the company, there is almost no limit to the amount of and type detail that could be displayed at the kiosk.

...

Integrated Sensor Radio Frequency Identification (ISRFID)

Description: The integrated sensor radio frequency identification system (ISRFID) is a performance centered design tool developed for logistics workers to alert in-storage and in-transit exceedences of conditions like temperature, pressure, and humidity that can be corrected to prevent damage to high-value assets. As a by-product, inventory and transportation system managers gain valuable information that leads to total asset visibility and enables improved decisions for better utilization of critical support assets.

...

Enabling Ubiquitous Sensing with RFID

Roy Want, Intel Research

...

Another useful parameter to monitor is acceleration. Fragile and sensitive products such as computers, glassware, and artwork can withstand only limited stresses before incurring damage. Today some package delivery companies monitor such items using nonelectronic dye-based tags that change color if they receive an excessive impact or vibration - for example, in a truck or while being moved in a warehouse. RFID technology could make this process more efficient and cheaper by automatically detecting an impact event without the need to manually inspect each package.

...

Noninvasive monitoring

... A surgeon could place an RFID sensor in a patient's body during a single procedure; later the physician could use an external reader to periodically contact the device, perhaps during routine office visits, and obtain a report on this aspect of the patient's health.

...