PLCC

Particle Interconnect PLCC

Particle Interconnect PLCC universal test socket

Nesting multiple packages in one design.

0.050" pitch, 20-84 lead with coplanar verification built-in.

|

|

Controlled impedance to lead of package / die pad

Controlled impedance to lead of package

|

|

| Schematic for controlled impedance socket. | Surface of PLCC J-Lead after 30,000 insertions. Surface finish of lead passed steam aging test. |

Controlled impedance socket

44 pin controlled impedance Particle Interconnect PLCC socket or interposer with singulate leads. Decoupling capacitors are within 0.100" of PLCC pad.

|

|

| Printed circuit board layout | Mechanical hold down |

Circuit layout for controlled impedance socket

D.U.T. board layout use for TDR measurement. The traces are narrowed to compensate for Z0 change due to devices present in the socket.

|

|

TDR of controlled impedance Particle Interconnect socket (interposer) on load board

|

|

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

- Cursor at contact point on diamond dust/diving board with no part in socket.

- Trigger is continuously running at 10.0 kHz with step on.

- Demonstrated controlled impedance connector from contactor board to mother board using Particle Interconnect with impedance tolerance of 50 Ω ± 1 Ω.

- Controlled impedance of J-lead going to package.

- Compensation (Point 2 on graph) to neutralize internal inductance and capacitance of PLCC package (Point 3 on graph).

- Particle Interconnect is 10 times better than SMA connector (Point 1 on graph).

- Additional work by MMS, TI, and HP.

Test results

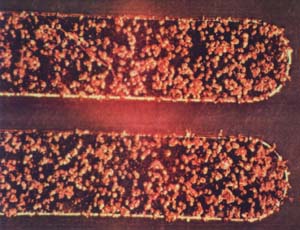

PLCC - J-Lead

Magnification 75x.

|

|

Magnification 150x.

|

|

SEM of pad probed by Particle Interconnect rigid socket

- Surface of PLCC J-Lead after 30,000 insertions.

- Surface finish of lead passed steam aging test.

Gold plated Particle Interconnect PLCC socket

Problem of current technology is that Gold is removed during wiping.

|

|

| PLCC leads. | Closeup |

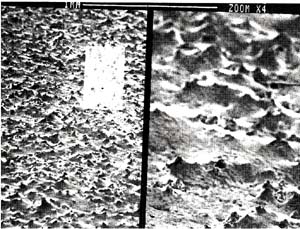

SEM of Gold plated Particle Interconnect PLCC socket

|

|

| 80 x magnification. | 150 x magnification. |

SEM's of contact surface

Tin-Lead solder over Nickel coated particles.

22x magnification with 88x zoom view.

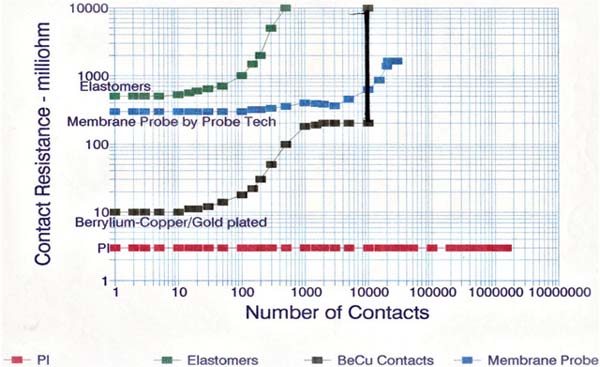

Lifetest comparison of Particle Interconnect vs. other sockets

Tested to failure.

This graph illustrates the exceptionally long remate life the Particle Interconnect coating provides a contact. Since the non-wiping action of the particles does very little damage to the mating surface, contacts last for 1,000,000 insertions or more. While this number is higher than the most applications require, it does testify to the robustness of connections using Particle Interconnect coatings.

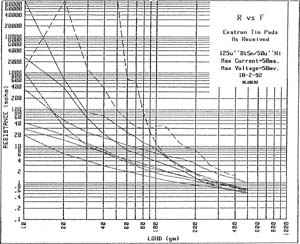

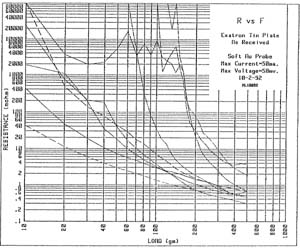

Contact resistance (milli-Ohm) vs. holddown force (gram-force)

Courtesy of Amp

These graphs show how Particle Interconnect coated contacts compare to traditional scrubing contact surfaces as regard to contact force and resistance. They illustrate the exceptionally low contact force of Particle Interconnect, showing this force to be at the test limit of 10 grams.

More importantly, the graphs show how consistently Particle Interconnect coatings perform between remate cycles. While tin and gold plated contacts 40 to 100 gram range initially, this performance was inconsistent and tended to degrade between remates because of oxide growth.

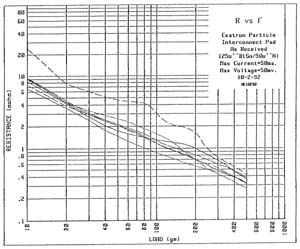

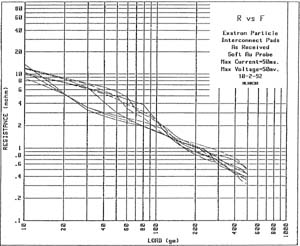

0.25" diameter hemispherical probes vs. 63/37 tin-lead coated surface.

| Bright tin probe vs. control (no PI) | Bright tin probe vs. 20-25 μ PI |

|

|

|

. 0.010" BeCu, 0.250" Ni, 0.150" SnPb. . 20 to 80,000+ milli-Ohms, 1 to 9 remates. . No scrubbing action. |

. 0.010" BeCu, 0.250" Ni + PI, 0.150" SnPb. . 6 to 9 milli-Ohms (one ignored), 1 to 6 remates. . No scrubbing action against PI. |

| Gold Probe vs. Control (no PI) | Gold probe vs. 20-25 μ PI |

|

|

|

. 0.010" BeCu; 0.250" Ni; 0.150" SnPb. . 20 to 80,000+ milli-Ohms, 1 to 9 remates. . No scrubing action. |

. 0.010" BeCu; 0.250" Ni + PI; 0.150" SnPb. . 8 to 14 milli-Ohms, 1 to 8 remates. . No scrubbing action against PI. |