Lead Frame

Examples

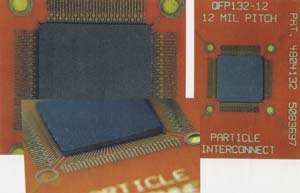

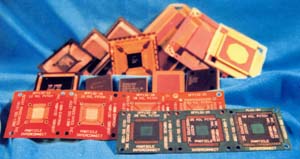

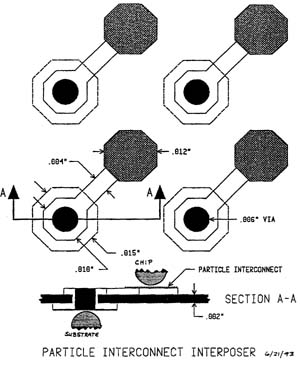

Particle Interconnect Package (PIP)

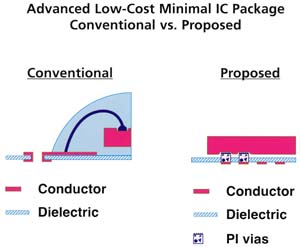

Advanced low-cost minimal IC package.

|

|

| QFP 132 lead, 0.012" pitch OLB (Outer Lead Bond). | Leadframe / Chip-On-Board socket & carrier. |

|

|

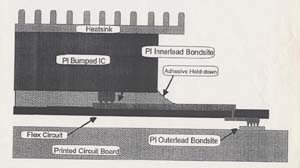

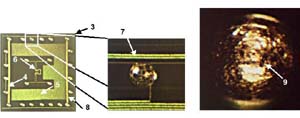

Particle Interconnect lead frame package

|

|

| Solder bumped chip (ILB) on Particle Interconnect lead frame (OLB). | Particle Interconnect bumped chip (ILB) on Particle Interconnect lead frame (OLB). |

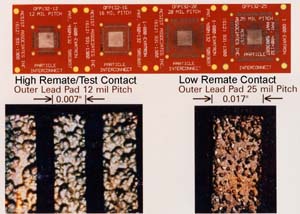

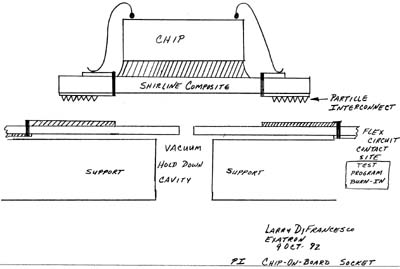

Alternative PI lead frame package has socket built-in at OLB

Temporary, or permanent contact even in presence of adhesive, grease, or solder.

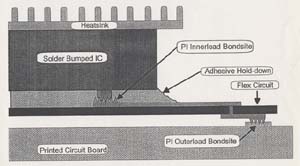

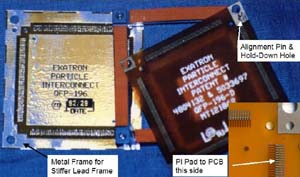

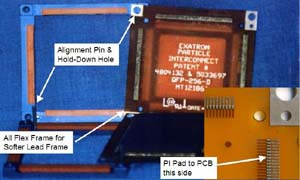

Alternative Particle Interconnect lead frame with holddown

Removable single unit - proof of concept.

|

|

| 0.025" pitch, 196 lead, ceramic QFP. | 0.020" pitch, 256 lead, ceramic QFP. |

Alternative Particle Interconnect lead frames vs. standard packages

Successful projects

Particle Interconnect - Hughes Aircraft 1988 - 1989

50,000 die joint production test venture.

Before burned-in:

- No bump deformation.

- Die Sn/Pb 3/97, socket Au 100, load 1 gm/mil2 pad to socket. Burned-in 125 ° C for 168 hours. Particles milled into gold ceramic ink and fired onto ceramic substrate. (Depression in center of bump is aluminum die pad covered by protective passivation layer.)

|

|

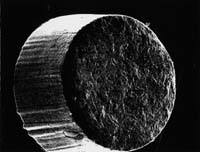

| 50x bumped chip before pressing against PI gold thick film. | 500x bump before contacting PI. |

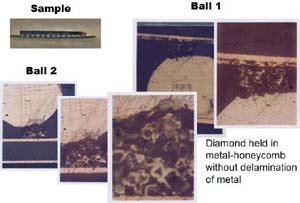

After burned-in:

- No bump deformation.

- PI/gold bonded to tin/lead bump and was ripped off substrate. Resulting in using nickel as higher strength Particle Interconnect bond layer in future test socket/temporary contact usages and other metal combinations in permanent usages.

|

|

| 50x bumped chip after pressing against PI gold thick film metal matrix with 1 gm/mil2 load. | 500x bump after contacting PI, metal matrix is on bump. |

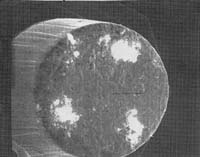

Particle Interconnect - Hughes environmental test die

Particle Interconnect removable MCM die socket.

100% of 500 die lot survived 4x Mil-Std-883C.

- Particle Interconnect with both adhesive and mechanical hold-down of chips while accumulating 4 runs of:

- 168 hours (672 hours total) 125 ° C for burn-in (other test passed are continuous 125 ° C),

- 500 cycles (2,000 cycles total) -55 to +125 ° C fast ramp MIL-STD-883C shock test,

- 24 hours (96 hours total) in salt/fog corrosion test,

- 24 hours (96 hours total) HAST (Highly Accelerated Stress Testing) pressure chamber (30 psi, +125 ° C pressure pot),

- Results in 50,000 die lot test prior to transfer into production.

- 96/4 Pb/Sn reflowed plated bump to spherize with special passivation configuration.

- Die orientated same as CAD picture for clarity (see: Removable die MCM - L/D/C).

- Note contact resistance test pads on left edge.

- Note traces for passivation crack detection.

- Note temperature sensors in center of die.

- Note traces for edge crack detection.

- Note traces for die heating.

- Note Particle Interconnect imprint.

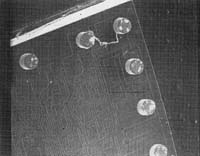

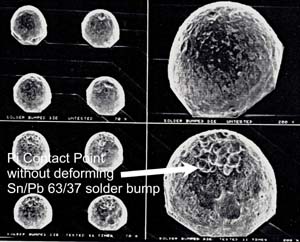

Particle Interconnect piercing SDRAM DDR1 package balls

- Demonstrating damage free performance when exposed to excessive loading.

- 60 pounds of force on 60 balls.

- Note minor depth of penetration.

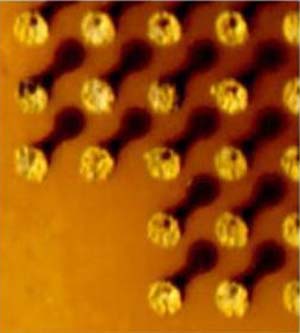

Particle Interconnect - MMS - TI - HP bare die probe

Proof of removable Known-Good-Die. Note single layer of particle on pad.

IEEE Transactions on Components, Packaging, And Manufacturing Technology

A Bare-Chip Probe for High I/O, High Speed Testing

Alan Barber, Keunmyung Lee, and Hannsjorg Obermaier

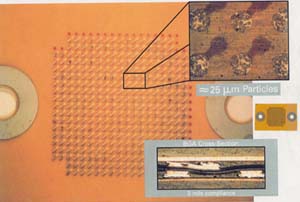

Particle Interconnect - Sandia Lab Known Good Die (KGD)

Known-Good-Die probe/burn-in. Proof of removable die MCM-L/D/C.

- 0.030" pitch 19x19 miniBGA.

- Burn-in at 125 ° C, 168 hours.

- 0 failures, 100+ runs, no deformation.

|

|

| 0 failures, 11 runs shown above. | Particle Interconnect surface mount BGA socket. |

|

|

| Particle Interconnect - Sandia mBGA interposer schematic. | Sandia mBGA interposer |