Mechanical Diffusion Welds

Having demonstrated temporary joint at room temperature. And permanent welding at approx. 150 ° F under light pressure (1.8 gm/mil2) in one second, that maintains parent metal material strength.

Temporary contact

Demonstrating temporary contact

Tab impression, very low pressure, at room temperature.

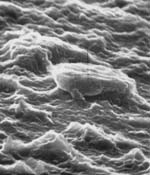

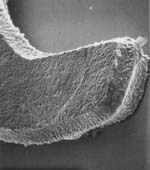

Particles plated onto tab frame by Abrasive Technologies, test done at Hughes Aircraft.

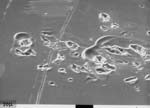

Particle coated copper tab frame impression in aluminum substrate (10,000x magnification).

|

|

Demonstrating temporary contact in overlapping fashion

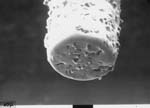

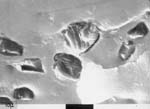

Aluminum coated microscope slide probed twice with drill bit made of aluminum coating over 10 micron diameter diamond particles.

Drill bit magnification: (a) 500x; (b) 2000x, 60 degree angle; (c) 5000x, 60 degree angle.

Aluminum examined at 60 degree angle, magnification: (d) 1000x (e) 5000x (f) 5000x.

Indentation (f) corresponds to drill bit(c).

| a | b | c |

|

|

|

|

|

|

| d | e | f |

Permanent cold weld

Tab frame cold welded to metal substrate

After pull test.

|

|

|

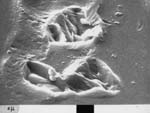

| Diamond particles in a nickel matrix on tab frame leads, sputter coated with aluminum (50x magnification). | Demonstration of cold fusion weld at 1.8 gm/mil2 at approx. 150 ° F bonding parameters. 3 x 9 mils area supported in excess of 80 grams prior to pulling a plug out of glass microscope slide (300x magnification). | Temporary contact with no cold fusion welding under 1.8 gm/mil2 pressure at room temperature on a microscope slide covered with aluminum (300x magnification). |

Another tab frame cold welded to metal substrate

Aluminum to Aluminum, 300x magnification. Prior to pull test.

|

|

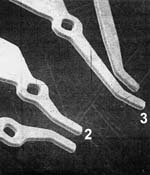

| Tab position two. | Tab position three. |

After pull test.

|

|

|

| 60x magnification. | The particles in nickel matrix plated onto the copper tab frame separated at the tab frame plating boundary (300x magnification). | Glass pulled out of microscope slide (300x magnification). |

Aluminum to aluminum cold weld

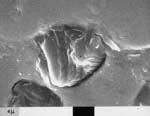

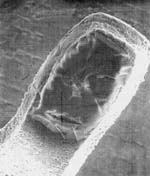

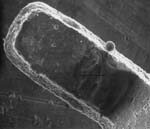

Aluminum coated drill bit with 10 micron diameter diamonds probing mirror smoothed aluminum

(a) 2000x magnification, 60 degree angle.

First sign of cold diffusion weld, showing the site where aluminum coating is peeled off.

(b) 2000x magnification, 60 degree angle.

First evidence of cold diffusion weld. Aluminum coating on diamond drill bit is peeled off and left on mirror smooth aluminum as result of welding.

|

|

| a | b |