Battery Terminal

Test results

Examination of particle uniformity

|

|

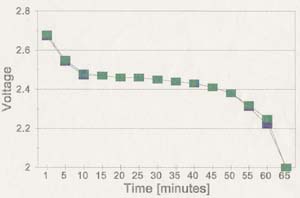

Battery discharge rate

Particle Interconnect vs. 4 weld spots, 0.200 Amp current.

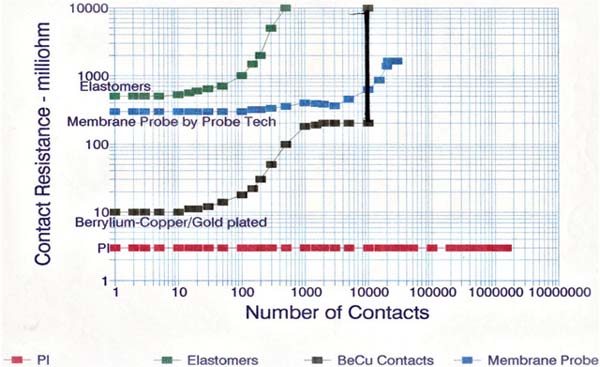

Lifetest comparison of Particle Interconnect vs. other sockets

Tested to failure.

This graph illustrates the exceptionally long remate life the Particle Interconnect coating provides a contact. Since the non-wiping action of the particles does very little damage to the mating surface, contacts last for 1,000,000 insertions or more. While this number is higher than the most applications require, it does testify to the robustness of connections using Particle Interconnect coatings.

Examples

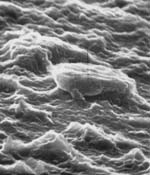

Demonstrating temporary contact

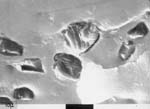

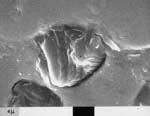

Tab impression, very low pressure, at room temperature.

Particles plated onto tab frame by Abrasive Technologies, test done at Hughes Aircraft.

Particle coated copper tab frame impression in aluminum substrate (10,000x magnification).

|

|

Demonstrating temporary contact in overlapping fashion

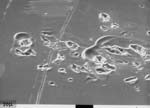

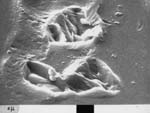

Aluminum coated microscope slide probed twice with drill bit made of aluminum coating over 10 micron diameter diamond particles.

Drill bit magnification: (a) 500x; (b) 2000x, 60 degree angle; (c) 5000x, 60 degree angle.

Aluminum examined at 60 degree angle, magnification: (d) 1000x (e) 5000x (f) 5000x.

Indentation (f) corresponds to drill bit(c).

| a | b | c |

|

|

|

|

|

|

| d | e | f |